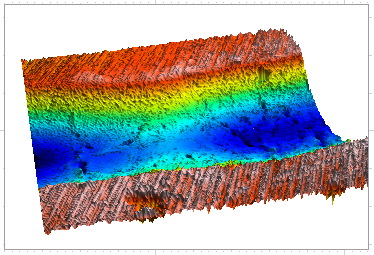

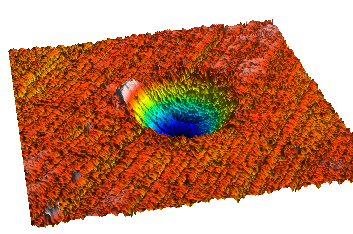

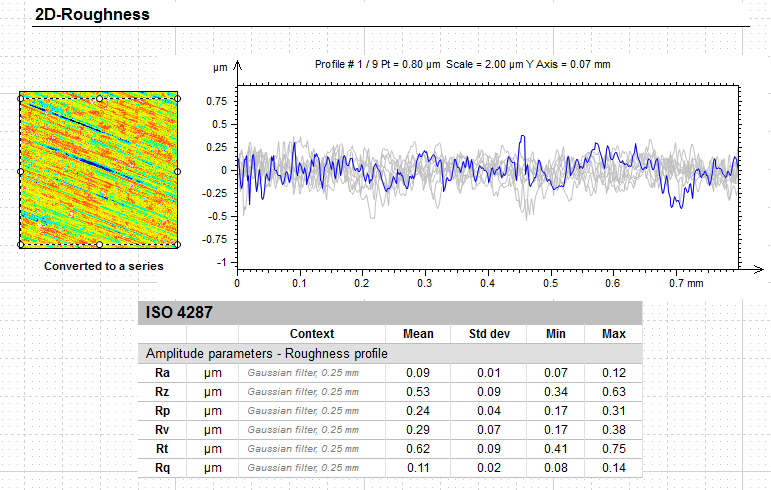

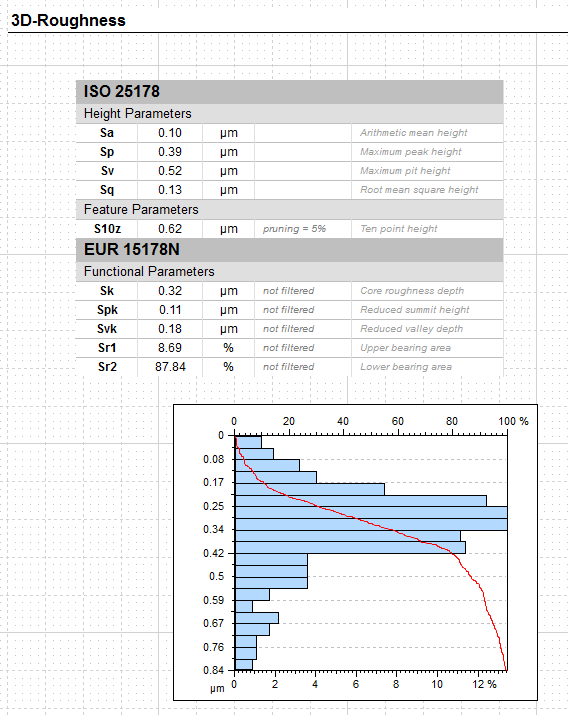

With the confocal microscope, we can measure 3-D surfaces with the highest resolution and this helps us particularly with the quantification of (low) wear in our friction and wear simulations. Depending on the requirements of the customer, the technique can be an additional measurement technology to the well known 2D profiles and light optical microscopy measurements of wear scars.

Whereas conventional and standard measurement techniques have been sufficient to compare good – medium – bad products, they are often not sufficient to distinguish good – better – best products and they can also lead to measurement errors or measurement uncertainty.

In the coming months, we will develop a number of application examples of the technique and publish them for your information.

If you are interested in the measurement technique, or you may have some surfaces that require high precision measurement, you may contact us as we also offer contract measurement services.

Contact : Dirk Drees (ddrees@falex.eu) with subject ‘Confocal Microscopy’.