Test Design

Tribology challenges are everywhere and each requires a different set of solutions. The expectance of industries to produce more durable products, use more sustainable and efficient production processes, the replacement of conventional alloys by light weight and 3D printed components, regulatory pressures in chemical substances, all lead to an increased need for material and lubricant replacement or optimisation. When standard test methods no longer provide the answers, you need to take it one step further and perform a dedicated tribology research project. But finding the appropriate resources and knowledge in-house to do this at short notice is very difficult.

With Falex as your partner, it’s like having your own complete testing facility and scientific staff on hand. For more than 20 years, the Falex labs have been offering test infrastructure and experienced staff to the industry, and this activity is only growing as tribological challenges are increasing

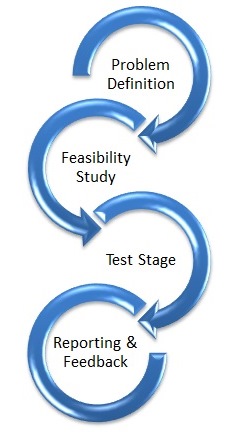

We approach a test project in 4 steps :

- Diagnose the problem : a good description of the application and the issue

- Feasibility of the test design: a parameter study, to confirm practical and economic feasibility of tests

- Test stage = Routine testing – test results, repeatability and reliability

- Reporting and Feedback

In every step you are closely involved to give feedback and adjust the program. Tribology tests are only useful if they are Relevant to the problem, Reliable in execution, Repeatable enough and Robust. We aim for these 4 ‘R’s.

This leads to optimal results and satisfaction. The test report is not always the end of our cooperation. We provide durable support in the form of routine test contracts or provide you with the test equipment.

Some case examples

Grease Stiction Property

Read more about this topic in this Falex Tribology Case Study

Greases and lubricants

Greases are widely used in machinery and automotive components to protect them from friction and wear losses.

As a result, interaction properties like adherence of greases to the substrate, cohesion or consistency and tackiness become crucial factors and often dictate their performance.

All these properties are related to microstructural aspects of grease like thickener network, wetting agents and additives. Falex MUST Instrumented Indentation Module can be used to quantify and characterise these interaction properties through approach-retraction test.

Ecological

Greases are widely used to lubricate heavy wire ropes and to protect them from corrosion.

Recently water-based eco-friendly greases were introduced, as they offer advantages like room temperature application, less use of reagents or cleaning agents, and availability in smaller quantities with overall impact on cost.

Before commercialising, the wear protection properties of water based greases must be tested in comparison with conventional greases. The Falex Four Ball Wear test method ASTM D2266 can be successfully used to compare the new waterbased lubricants with conventional ones.

Eco-Friendly Wire Ropes Greases

Read more about this topic in this Falex Tribology Case Study

Electrical Connectors Reliability

Read more about this topic in this Falex Tribology Case Study

Electronics

Today, electrical connectors are present in many products from cars to mobile phones and other portable electronics.

Under vibrations, connectors slide over very small displacements and generate particles that interrupt the electrical connection. Such small displacements are hard to lubricate and damage must be avoided in another way.

The geometry of the connector can be changed, to reduce mechanical pressure, or wear resistant coatings can be applied, or a suitable grease can be used to avoid the fatal fretting damage. The different approaches can be tested by a dedicated fretting test.

Medical

Soft coatings with antibacterial and antiseptic properties are of interest in the implant industry. Naturally, good adhesion of this coating to the implant substrate is important especially during insertion operation.

Testing soft tissues is a difficult task because of creep or the material and because of contact load/pressure limitations. The low load microtribometer is ideal for characterising such coating through scratch tests.

In the European framework project ‘NEWBONE’, Falex is developed new test procedures for quantifying adhesion of such bio-nanocomposite gels on polymer resin based substrates.

Thin or Soft Coatings

Read more about this topic in this Falex Tribology Case Study

Friction Modifiers

Read more about this topic in this Falex Tribology Case Study

Petrochemical

Energy reduction is a hot topic. Both in transportation and in power production, the drive is towards lower frictional losses. This can be achieved in part, by dedicated friction-reducing additives in the lubricants. Each application, be it the piston-liner contact, crankshaft bearings, turbines, gears, drivetrain components, have their own set of operating conditions, so friction modifiers need to be evaluated over a range of parameters, such as temperatures, pressures and velocities.

Contact us to discuss your needs.

We’re always here to help. If you’re interested in any of our services please give us a call or fill out the contact form and we’ll assist in any way we can.